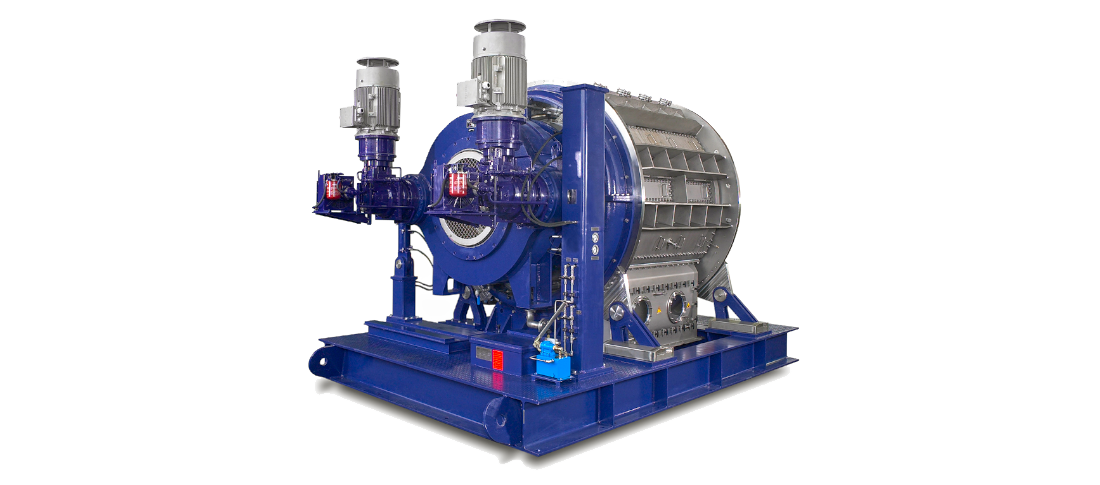

The BHS Rotary Pressure Filter is a continuously operating filter for pressure filtration, cake washing and drying of high solids slurries with full containment and automatic cake discharge. The technology is based upon a slowly rotating drum, less than 2 rpm, with individual cells containing the filter media and isolated process zones.

Filtration is driven by pump pressure of up to 7 barg with a temperature range of 200° Celsius. Positive displacement washing or counter-current washing follows filtration. Multiple washing steps as well as solvent exchanges, steaming and extraction can also be accomplished. Finally, the cake is dried by blowing hot or ambient-temperature gas through the cake.

The Filter has a uniquely designed discharge system, which provides for atmospheric discharge from pressure filtration. After automatic cake discharge, the filter cloth is washed; the clean filter cloth then re-enters the feeding / filtration zone thereby continuing the process. All solvent and gas streams can be recovered separately and reused in the process to minimize their consumption.

- Deep Cake (Up to 160mm)

- Slurry Discharge

- Pressurized Filtrate Discharge

- Pressurized Cake Discharge

- High Pressure Design (7barg)

- Counter current washing

- Solvent exchange

- Steam drying

- Gas tight secondary containment

- Flexible alloy and polymer materials of construction

- Explosion proof classification

- Clean in place (CIP)

You have an inquiry for this item. Please send us

Mr. Lee Communication & Consultation for BHS-Sonthofen – Indonesia

E-mail : MrLeewenfu@outlook.com

Tidak ada komentar:

Posting Komentar